Constructing Your Dream Pallet Shed: A Step-by-Step Guide Using Free PDF Plans

Dreaming of a charming, functional shed without breaking the bank? This guide shows you how to transform free PDF pallet shed plans into a reality. We'll walk you through each stage, from selecting the perfect plans to enjoying your finished structure. Get ready to build your own rustic haven!

Choosing Your Free PDF Pallet Shed Plans

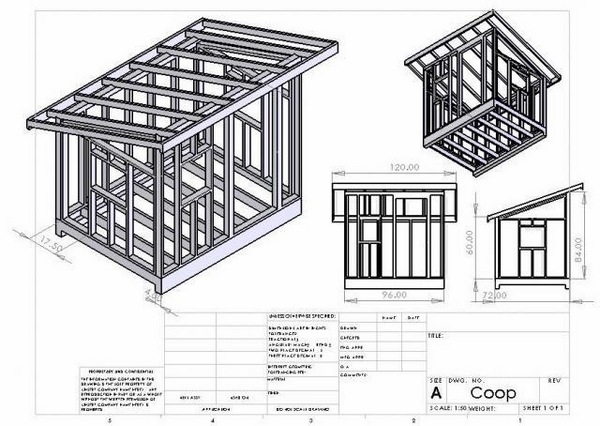

The internet offers a wealth of free pallet shed plans. However, careful selection is crucial. Start by searching for “free pallet shed plans PDF†on your favorite search engine. Look for plans with detailed diagrams, clear instructions, and a materials list. Consider the shed's intended purpose; do you need ample storage, a workshop space, or a simple tool shed? Choose plans that align with your needs and skill level. Pay close attention to the dimensions; ensure the shed fits comfortably within your designated area. Don't hesitate to compare several sets of plans before making your decision. A well-organized and easy-to-understand set of plans will significantly ease your construction process.

Gathering Your Materials and Tools

With your plans finalized, it’s time to gather the necessary materials and tools. Pallet selection is key. Inspect pallets carefully for rot, damage, or pest infestation. Prioritize sturdy, undamaged pallets made from pressure-treated lumber for longevity. Beyond pallets, you'll need additional lumber for structural reinforcement, roofing materials (consider metal roofing for durability), fasteners (nails, screws, or a combination), and any desired finishing touches like paint or stain. Your tool kit should include a hammer, saw (circular saw recommended for efficiency), measuring tape, level, drill, safety glasses, and work gloves. Investing in a quality power drill will save significant time and effort during assembly.

Essential Materials List (Check your specific plan for variations):

- Recovered pallets (number varies depending on plan)

- Additional lumber for supports and framing

- Roofing materials (metal, shingles, etc.)

- Nails, screws, and other fasteners

- Paint or stain (optional)

Constructing Your Pallet Shed: A Step-by-Step Approach

Follow the PDF plan meticulously, one step at a time. Begin by preparing the groundâ€"leveling the area and potentially creating a foundation (depending on the plan). Next, assemble the shed's base according to the instructions. This usually involves securing the pallets together to create a sturdy foundation. Carefully erect the walls, ensuring proper alignment and support using the supplemental lumber for reinforcement where needed. Install the roof frame and then the roofing material itself. Pay close attention to the details and use the level frequently to maintain squareness throughout the construction. Remember, accuracy in each step ensures a stable and long-lasting structure.

Finishing Touches and Final Inspection

Once the main structure is complete, add any desired finishing touches. This might include painting or staining the wood for protection and aesthetics. You might also want to add doors and windows, following the instructions in your plans. After completing the assembly, thoroughly inspect the entire shed, checking for any loose parts or potential safety hazards. Ensure all connections are secure and the roof is weatherproof. Your new pallet shed is now ready to be enjoyed! Remember that proper maintenance will extend its lifespan.

Safety First!

Safety should always be your top priority. Wear safety glasses and gloves at all times. Use caution when operating power tools, and ensure proper ventilation when working with paint or stain. If you're unsure about any aspect of the construction, consult a professional. Building a pallet shed is a rewarding project, but safety should never be compromised.